Beam and column detailing is far more than just drafting lines on a plan. It is the engineering language that turns calculations into buildable reality. For structural engineers and designers in Florida, where hurricane-force winds, high humidity, and strict local building codes define the construction environment, the quality of beam and column detailing has a direct impact on safety, durability, and project cost.

Without clear, accurate detailing, contractors are left guessing. And in structural engineering, guesswork can lead to costly rework or, worse, structural failure. Today, we discuss the beam and column detailing, its process, and its importance in maintaining a successful and safe construction project.

What are beams and columns in building structures?

Columns are vertical components used in structural engineering that are intended to support and move loads from the superstructure, which includes walls, floors, and roofs, down to the foundation. Beams are horizontal components that convey loads to columns from slabs, roofs, or other beams.

The intersection of beams and columns is more than a meeting point – it’s a pivotal node in the load path. In Florida’s building environment, this node has to handle not only gravity loads but also extreme lateral forces from windstorms or, in rare cases, seismic activity.

When detailed correctly, these components distribute loads exactly as the designer intended, maintaining structural integrity throughout the life of the building.

Also read: What are MEP Drawings in Construction, and What is their Significance?

What is the detailing of beam-column joints reinforcement?

Reinforcement detailing is the process of specifying exactly how steel bars (rebar) are placed, bent, spliced, and anchored within concrete members. A strong reinforcement detail provides:

- Bar size and spacing: Selected based on bending and shear demands.

- Anchorage details: Hooks, bends, and embedment lengths for adequate force transfer.

- Lap splice lengths: Designed to meet code requirements for tensile and compressive continuity.

- Concrete cover: Thickness of concrete around rebar to protect against corrosion, especially important in Florida’s coastal climate.

- Special detailing for corners and joints: To prevent weak points in areas where stress concentrations occur.

In reinforced concrete beam-column joints, reinforcement detailing also controls crack widths, prevents premature failures, and helps structures perform as expected during high wind or cyclic loading events.

Also read: Avoiding Construction Site Errors through Accurate Structural Plans

What are the four types of beam and column detailing?

Details for beams and columns can change based on the material and structural system. Four major types are common in Florida’s engineering practice:

- Reinforced Concrete Beam-to-Column Detailing: Includes RCC beam-column joints, stirrup spacing, and anchorage rules from ACI 318 and ACI 352 guidelines. Requires attention to seismic detailing provisions, even for wind-resistance design.

- Steel Beam-to-Column Connection Detailing: Uses bolted or welded connections per AISC 360 and AISC 358 standards. Requires clarity on bolt grades, weld types, and stiffener placement for heavy load areas.

- Composite Beam and Column Detailing: Combines steel and concrete for efficiency. Needs detailing for shear studs, composite deck connections, and reinforcement integration.

- Precast Beam and Column Detailing: Involves factory-fabricated members with on-site assembly. Requires precision in embed plate location, grouting details, and tolerance allowances.

Each type carries its own detailing challenges, and Florida’s building code often requires adjustments for wind-load resistance and durability in humid, saline environments.

Types of Beam-to-Column Connections

1. Moment-Resisting Connections (Rigid)

Designed to resist both bending moments and shear forces, these connections keep members from rotating relative to each other. They are common in hurricane-resilient frames because they help maintain the building’s shape under lateral loads.

2. Shear Connections (Simple)

Allow rotation while transferring shear forces. They are easier to fabricate and install but are not meant to resist significant bending moments. Often used in non-moment frames or as secondary framing connections.

Fundamental Details Every Drawing Should Include

For steel structures

- Bolt size, grade, and tightening method (snug-tight or fully tensioned)

- Weld specifications – fillet vs. groove welds, electrode classification, and weld length

- Shear tab thickness and bolt spacing to avoid premature tearing

- Stiffener plate dimensions for deep beams or heavy loads

For reinforced concrete

- Longitudinal bar anchorage into columns

- Stirrup detailing to confine concrete and improve ductility

- Lap splice locations away from maximum moment zones

- Clear labeling of bar marks for fabrication clarity

Also read: Mastering MEP Coordination: How to Seamlessly Integrate Architectural, Structural, and Building Systems

Case Study: Lessons from Connection Failures

The 1994 Northridge earthquake in California exposed the vulnerability of welded steel moment connections to brittle fracture. Although Florida is not seismically active, the event taught the industry valuable lessons about ductility and redundancy – principles that also apply to high wind cyclic loading during hurricanes.

Source: Anastasiadis, Anthimos & Marius, Mosoarca & Formisano, Antonio. (2024). Conceptual Investigation of the Northridge’s Earthquake Structural Failures on Steel MRF by the Aid of Swiss Cheese Model. 10.1007/978-3-031-62884-9_72.

Beam and Column Detailing Process

A high-quality beam and column detail is the result of a systematic process that balances design intent, code compliance, and constructability.

#1 Interpretation of Structural Design: Review load transfer mechanisms, deflection limits, and moment-shear interaction for beams and columns.

#2 Selection of Applicable Standards: In Florida, most projects follow the Florida Building Code, referencing ACI 318 for concrete and AISC 360 for steel.

#3 Reinforcement or Connection Geometry: Define hook shapes, bar bending schedules, bolt layouts, and plate dimensions.

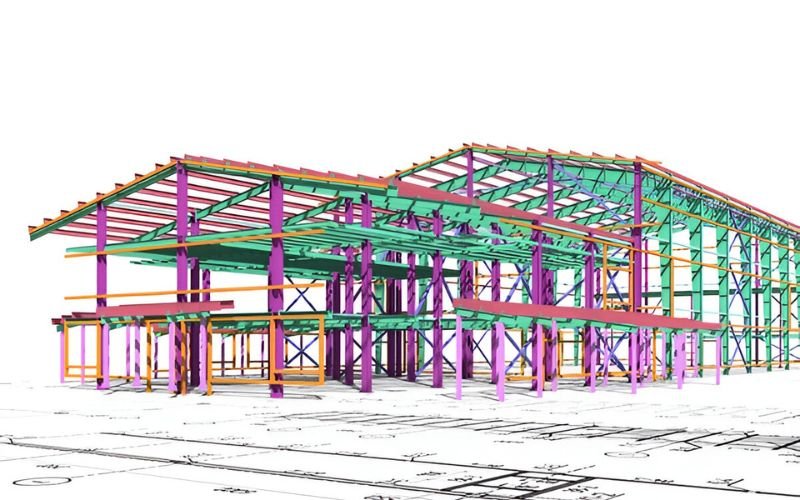

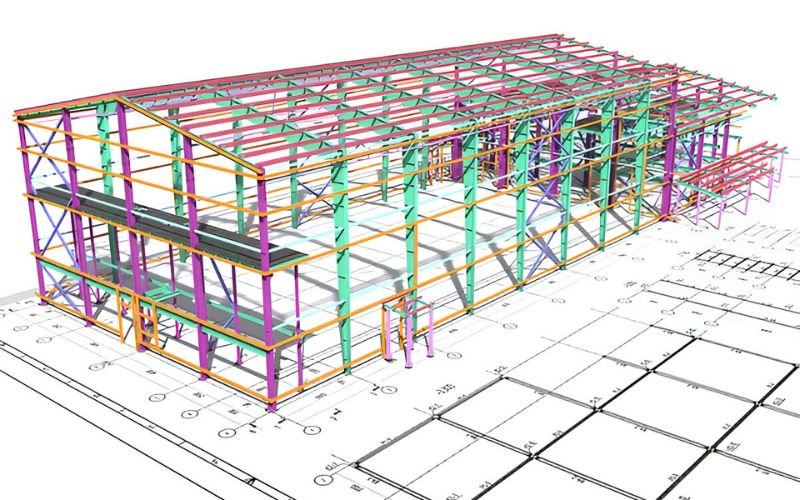

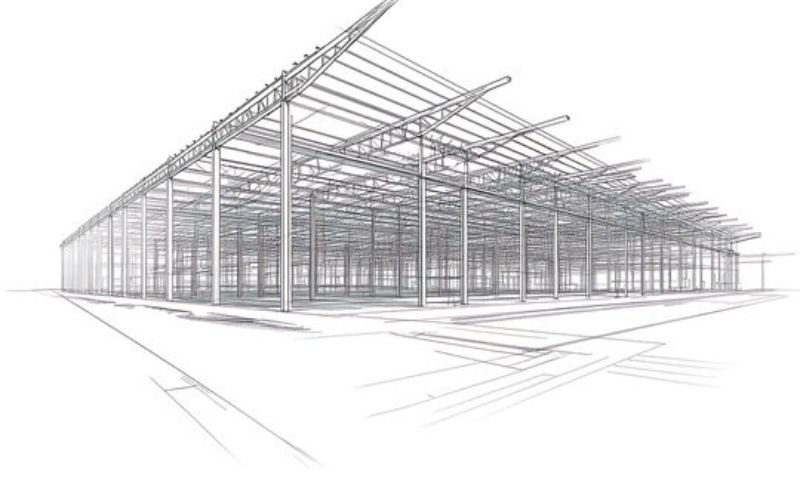

#4 Drawing Production: Use software like AutoCAD, Revit, or Tekla to produce both 2D plans and 3D models for improved clarity.

#5 Review and Validation: Peer review for dimensional accuracy, compliance, and buildability before issuing for construction.

View our MEP Drawings Portfolio

How the Beam and Column Detailing Is Presented

- 2D Drawings: Traditionally presented as plan views, sections, and elevations in structural drawing sheets (often part of a larger construction drawing package).

- Bar Bending Schedules: Tables listing each reinforcement bar’s size, shape, length, and quantity, referenced with bar marks on the drawings.

- Connection Details: Enlarged callouts or detail views showing exactly how a beam meets a column, including reinforcement placement or steel plate/weld arrangements.

- Codes and Notes: Reference to design standards (e.g., ACI 318, AISC 360, FBC) and general notes for site execution.

- 3D Models (Optional): Increasingly, firms use 3D structural models in Revit, Tekla, or similar software to help visualize reinforcement and connection geometry – but these models are still extracted into 2D detail sheets for construction purposes.

View our 3D Renderings Portfolio

Regional Standards Comparison

| Parameter | ACI (USA) | Eurocode 2 (Europe) | IS 456 (India) |

| Minimum Concrete Cover (Columns) | 40 mm | 40 mm | 40 mm |

| Lap Splice Length (Tension) | 40 × bar dia. | 41 × bar dia. | 40 × bar dia. |

| Shear Reinforcement Spacing | ≤ d/2 | ≤ 0.75d | ≤ 0.75d |

(d = effective depth of member)

This table shows why regional code familiarity matters – even small differences can affect material quantities and long-term durability.

Why Proper Beam and Column Detailing Can Make or Break Your Construction Project

Inaccurate or incomplete detailing has real consequences. It can delay fabrication, cause site conflicts, increase material waste, and, in extreme cases, compromise the safety of the entire structure.

In Florida, where environmental conditions already test a building’s performance, sloppy detailing can lead to:

- Misaligned bolt holes in steel frames

- Reinforcement congestion at joints, making concrete placement difficult

- Short lap lengths that weaken tension zones

- Poor corrosion resistance due to inadequate cover

By preparing beam and column details with precision, structural engineers create a clear roadmap for contractors, helping projects run smoother and safer.

Also read: Delivery Design Palm Springs – Smarter Way to Approach Architecture

Florida-Specific Considerations for Beam and Column Detailing

- Hurricane-Force Wind Design: Higher lateral loads mean heavier reinforcement at joints and stronger connection plates.

- Corrosion Resistance: Use epoxy-coated rebar or stainless-steel reinforcement for coastal projects.

- Foundation Tie-In Details: Column base plates and anchor bolts must be detailed to resist uplift forces.

- Construction Tolerances: Allowances for thermal expansion and humidity-related material movement.

Explore our Areas of Expertise

Partner with Experts Who Know Florida’s Detailing Requirements

At Drawingstech, we treat beam and column detailing as a precision craft. Our structural drawings and drafting services leave no room for guesswork, making it easier for fabricators and contractors to execute exactly what the engineer intended.

We bring together creativity and technical accuracy, supported by advanced software and years of Florida-specific project experience. From RCC beam-column joints to advanced steel moment connections, our work reflects a deep understanding of both code and constructability.

If you are a structural engineer or designer in Southeast Florida and you want detailing that’s accurate, clear, and ready for real-world conditions, call (561) 574-9032 to schedule a consultation to discuss your project needs. Get in touch with us today for professional advice and assistance suited to your construction needs.

_____________

References

American Concrete Institute. (2019). Building code requirements for structural concrete (ACI 318-19) and commentary. American Concrete Institute. https://www.concrete.org

American Institute of Steel Construction. (2022). Specification for structural steel buildings (ANSI/AISC 360-22). American Institute of Steel Construction. https://www.aisc.org

American Society of Civil Engineers. (2016). Minimum design loads and associated criteria for buildings and other structures (ASCE/SEI 7-16). American Society of Civil Engineers. https://www.asce.org

International Code Council. (2023). Florida building code—Building. International Code Council. https://codes.iccsafe.org/codes/florida